INT is an industrial reality created with the aim of offering innovative solutions in the field of analysis, starting from current regulations. Thanks to the group concept (mechanical, electrical, software) developed over the years, it is the ideal and reliable partner for all those who want concrete solutions by entrusting highly specialized technical staff with extremely difficult issues such as analysis and emissions.

Vehicle Emissions Analysis Systems

The increasing attention paid to preserving the environment and health against the risks of pollution has led INT to develop continuous analysis systems for vehicle pollutant emissions. The systems are built for measuring both gaseous emissions and particulate matter generated by vehicles. The systems, studied and developed with primary automotive brands and/or accredited laboratories, utilize latest-generation technologies, aiming for innovative solutions.

Continuous Emissions Monitoring System (CEMS)

The increasing demand for control for the protection of the environment and health by notified bodies (EPA – ARPA) has necessitated the continuous monitoring of emissions. CEMS is defined as the system capable of continuously analyzing, monitoring, and recording the concentrations of gases and flow measurements emitted into the environment. INT positions itself as the ideal partner for integration thanks to its engineering and construction capabilities; it is capable of realizing turnkey systems complete with data acquisition and processing software, interfacing with the relevant bodies. They are built in cabinets, shelters, or on open frames in both safe area execution and ATEX explosion-risk area execution.

Gas/Liquid Analysis Racks

Correct measurement implies correct treatment of the samples to be measured. INT, in collaboration with major analyzer manufacturers (liquid – gas), is able to provide complete chemical-physical analysis systems; the systems can be interfaced with DCS/PLCs or equipped with their own systems that make them independent and autonomous. Depending on the application, the racks are made of painted carbon steel or stainless steel, complete with a canopy to protect the installed instruments. They can be complete with GRP or metallic cabinets depending on the areas of application.

Gas/Liquid Analysis Shelters

Correct measurement implies correct treatment of the samples to be measured. INT, in collaboration with major analyzer manufacturers (liquid – gas), is able to provide complete chemical-physical analysis systems; the systems can be interfaced with DCS/PLCs or equipped with their own systems that make them independent and autonomous. Depending on the application, the shelters, in addition to providing protection for the installed instruments (site conditions with T 0°C), can be manufactured for potentially explosive ATEX areas.

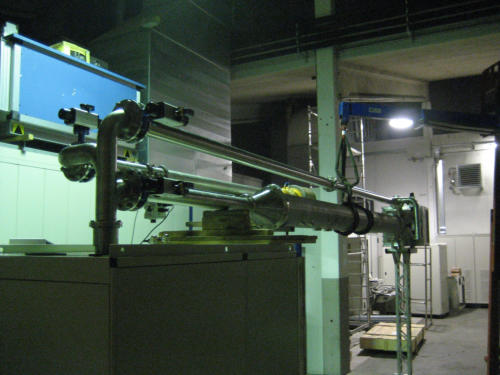

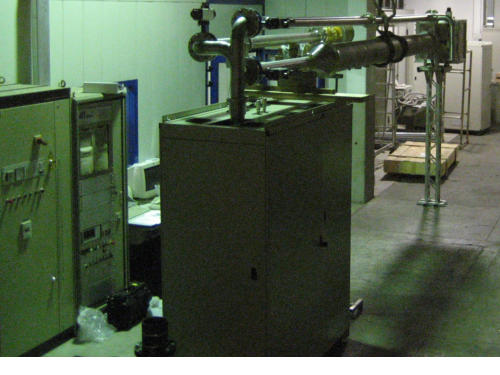

Sampling and Conditioning Systems

Thanks to the experience acquired over the last 20 years, INT takes on the role of a global partner alongside the customer for the quotation, engineering, and realization of sample treatment and conditioning systems, whether they are gases or liquids. The concept of sample treatment (reduction, maintenance of temperature and pressure, CO2 removal, dehumidification, etc.) guarantees a high degree of measurement quality. All this leads to a reduction in maintenance costs and correct plant operation with the resulting improvement in efficiency and quality.